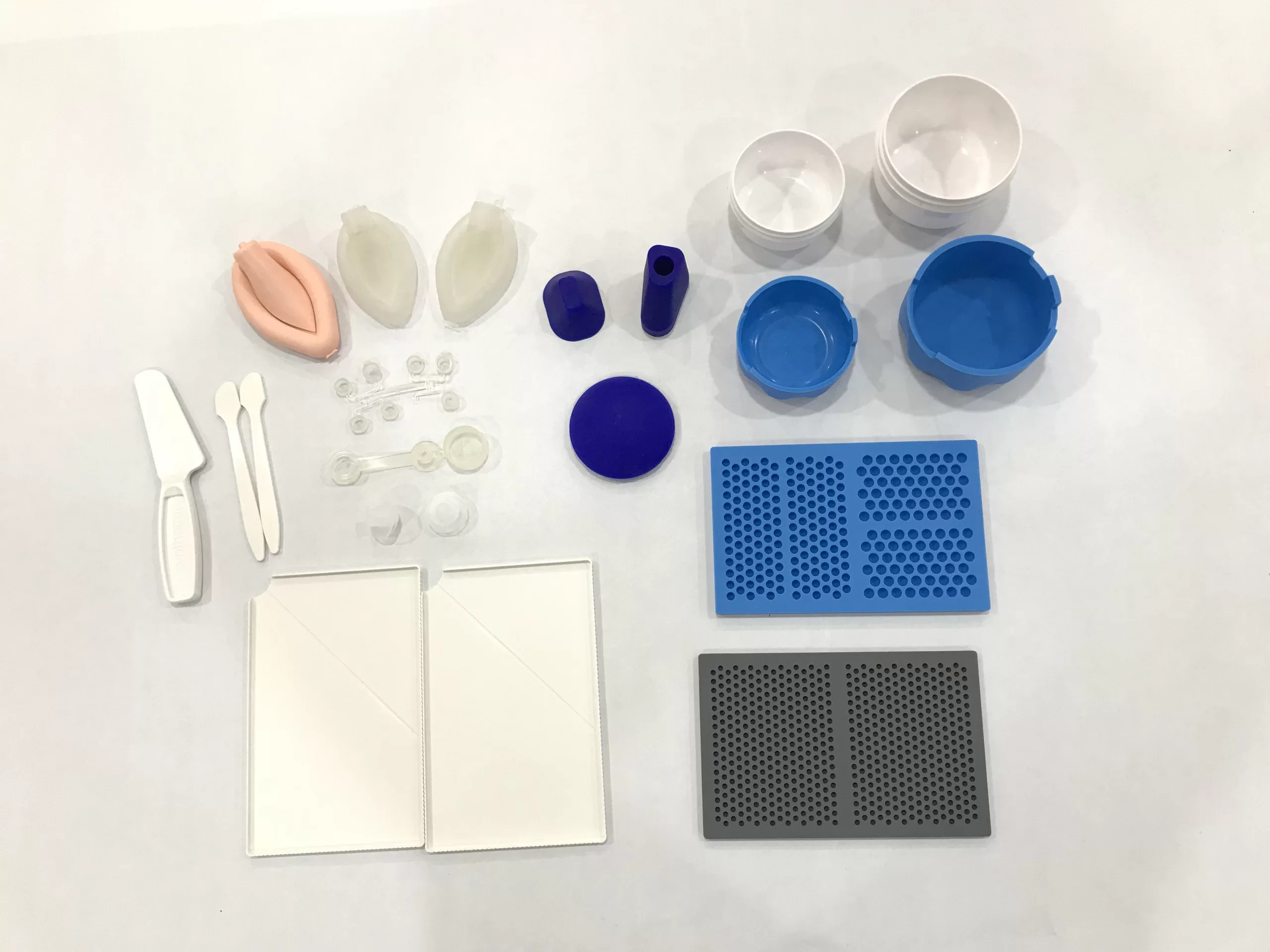

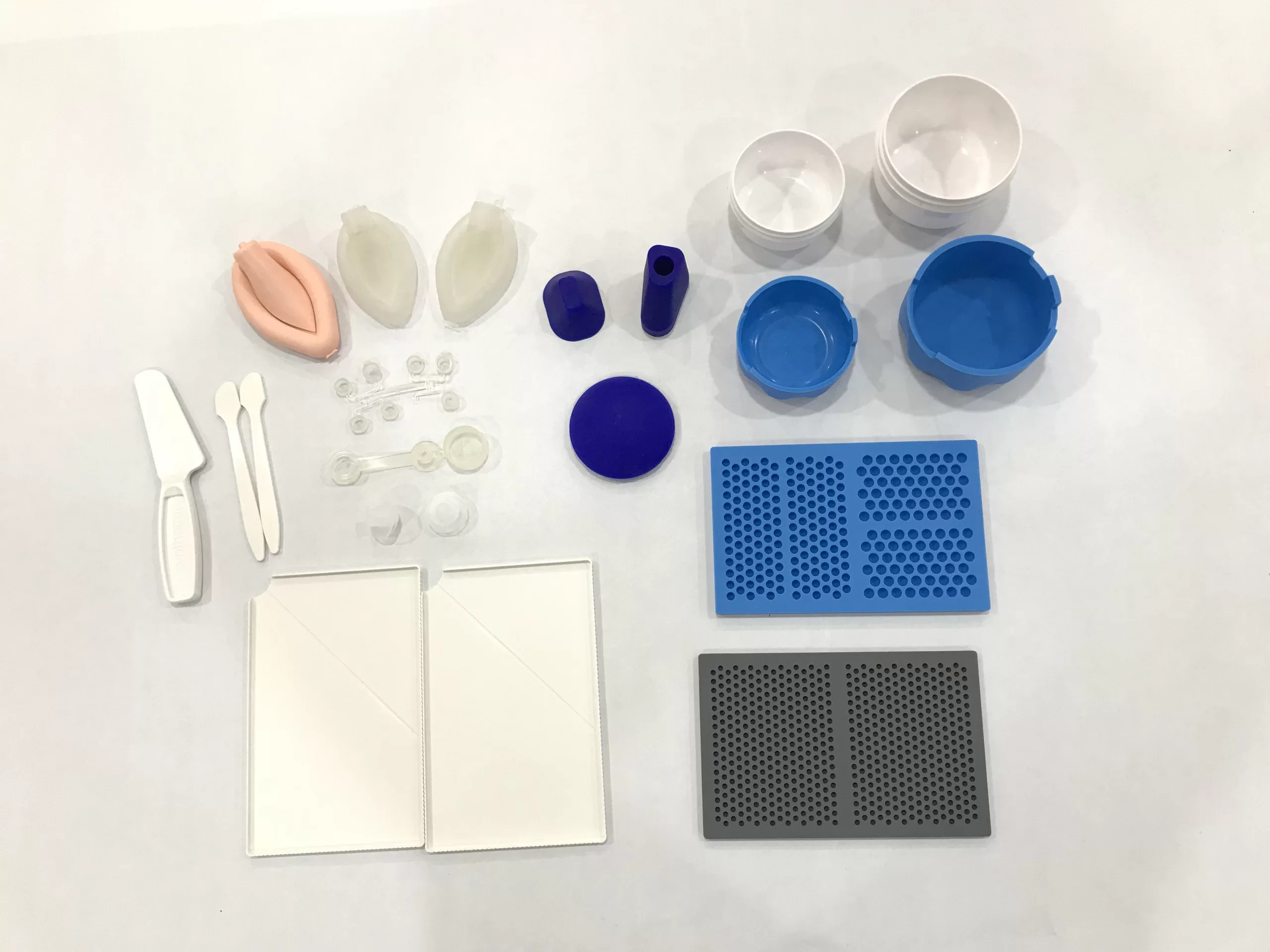

Our expertise lies in providing specialized LSR (Liquid Silicone Rubber) injection services. Through this advanced manufacturing process, we bring precision, quality, and innovation to the forefront of your product development. Our skilled team and cutting-edge technology work in harmony to ensure that your LSR components are meticulously crafted to meet the most demanding standards.

We bring accuracy and quality to every mould, ensuring that your designs come to life just as you envision them. With a focus on expertise, tailored solutions, and advanced technology, we deliver products that meet the highest standards. From material selection to quality checks, our streamlined process guarantees reliable outcome. Whether it’s for the automotive, electronics, or other industries, we adapt our techniques to fit your needs.

We offer customized solutions to fit your unique requirements. Our dedicated team guarantees accuracy and superior quality in each mould, ensuring your project surpasses the highest standards. With our stringent quality control and impeccable precision, your satisfaction is assured.

Our skilled team is dedicated to delivering precision and excellence in every mould, ensuring your projects shine with vibrant colours and impeccable quality. With a meticulous process that involves material selection, seamless colour integration, and rigorous quality checks, we guarantee outstanding results that meet the highest standards.

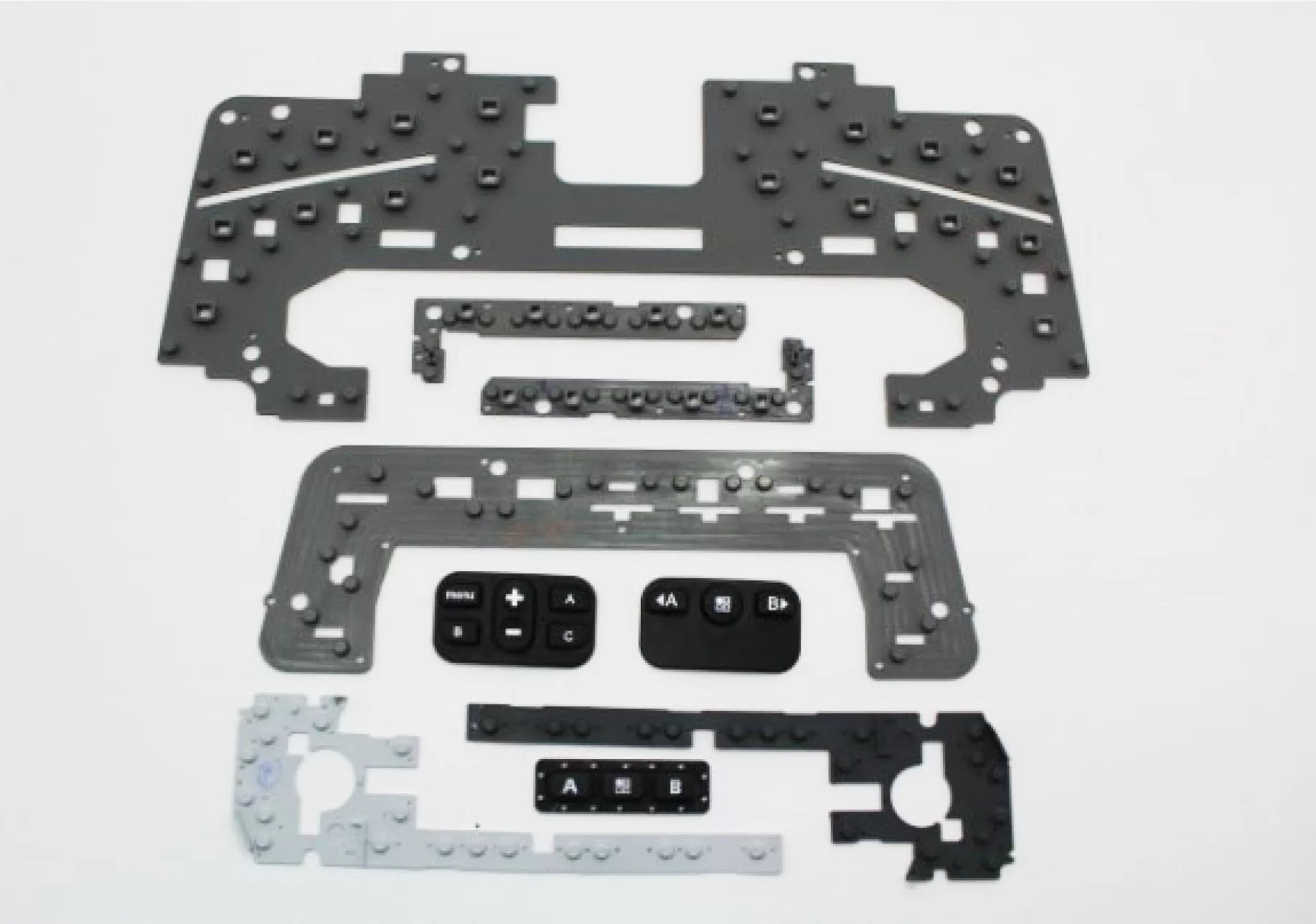

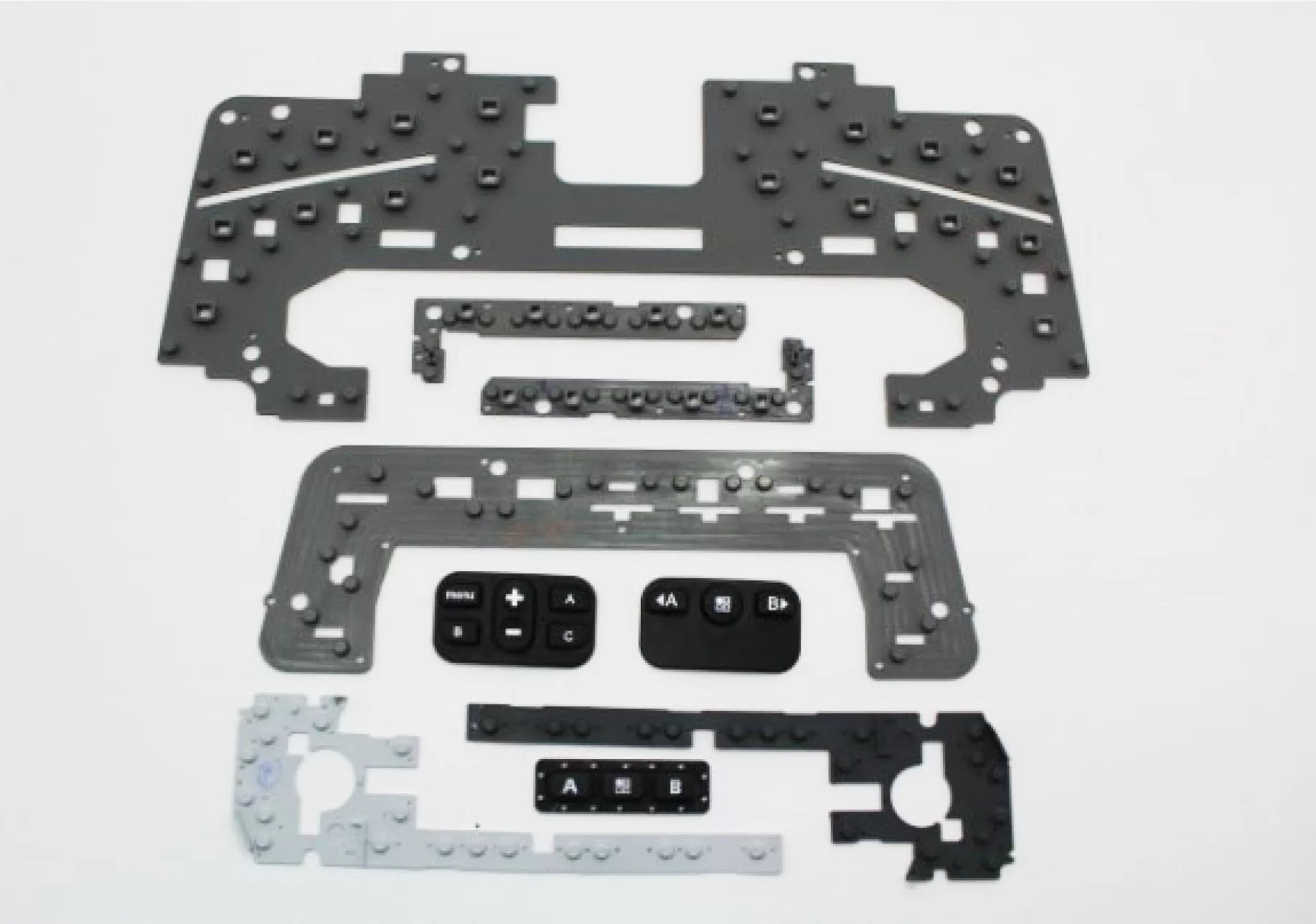

Our Finished Product

AMS Malaysia is a reliable custom rubber parts manufacturer in Malaysia. Our rubber parts are manufactured by our expert rubber moulding team, which include rubber adhesives, silicone compounders, liquid rubber moulding and injection moulding. We make it from scratch, redesign existing products to increase durability and safety, or create custom moulds for rapid prototyping. The custom-moulded parts can be designed according to your own specifications and needs.

AMS manufacturers supply a wide range of bespoke rubber parts for many applications. Our rubber moulding manufacturing process, rubber materials and associated processes utilize the highest workmanship and material quality. This includes a range of advanced injection moulded engineering elastomers.

We manufacture compression moulds and injection moulds to produce custom rubber parts. Most commonly; EPDM, NBR, TPE, TPU and Silicone. Please do not hesitate to contact us if you wish to discuss your rubber part, product or application. We are happy to provide technical expertise as necessary.

AMS Malaysia supply a wide range of bespoke rubber parts for many applications. Our rubber moulding manufacturing process, rubber materials and associated processes utilize the highest workmanship and material quality. This includes a range of advanced injection moulded engineering elastomers. We are experienced in the engineering of case joints for IP Rated products, often including such features as cable exit grommets and fixing seals. Please do not hesitate to contact us if you wish to discuss your custom rubber parts manufacturer, product, or application. We are happy to provide technical expertise as necessary.

LSR has a wide range of applications across industries such as automotive, electronics, medical devices, consumer goods, and more. It is used to manufacture parts such as seals, gaskets, O-rings, keypads, medical implants, and components for electronic devices.

LSR manufacturing offers several advantages including the ability to produce complex geometries with tight tolerances, excellent part consistency and repeatability, resistance to extreme temperatures and harsh environments, biocompatibility for medical applications, and long-term durability.

Working with a custom rubber parts manufacturer offers several benefits including access to specialized expertise, customized solutions tailored to specific requirements, cost-effectiveness through efficient production processes, and assurance of product quality and reliability.

When selecting a custom rubber parts manufacturer, consider factors such as their experience, capabilities, quality certifications, production capacity, lead times, and pricing. It’s essential to choose a manufacturer that can deliver high-quality products on time and within budget.